ПРОДУКЦИЯ » Швы для тяжелой техники » ДВС » ДВС-11/040, Исп.-1

Дилатационное устройство АКВАСТОП ДВС-11/040, Исп.-1 — это закладной деформационный шов длиной 3 метра, предназначенный для обустройства швов. Данное устройство подходит как для внутренних помещений, так и для открытых площадок. Предназначены для компенсации деформаций в горизонтальных и вертикальных конструкциях (полы, стены, потолки). Снижают нагрузки, вызванные усадкой, температурными перепадами. Он выдерживает давление до 200 МПа и обеспечивает безударный проезд техники.

9650,00 ₽

Цена за п.м.

Деформационный профиль ДВС-11/040, Исп.-1 — предназначен для обустройства деформационных швов на поверхностях, подверженных высоким нагрузкам. С его помощью можно обустраивать швы в местах, где давление достигает до 200 МПа, что делает профиль идеальным для применения на военных полигонах, в складских помещениях с интенсивным использованием погрузчиков на стальных колесах и других зонах с экстремальными нагрузками.

Особенности:

Применение:

Монтаж:

| Материал компенсатора | Сталь |

|---|---|

| Страна производства | Россия |

| Тип профиля | Прямой |

| Тип монтажа | Закладной |

| Нагрузка - МПа | 200 |

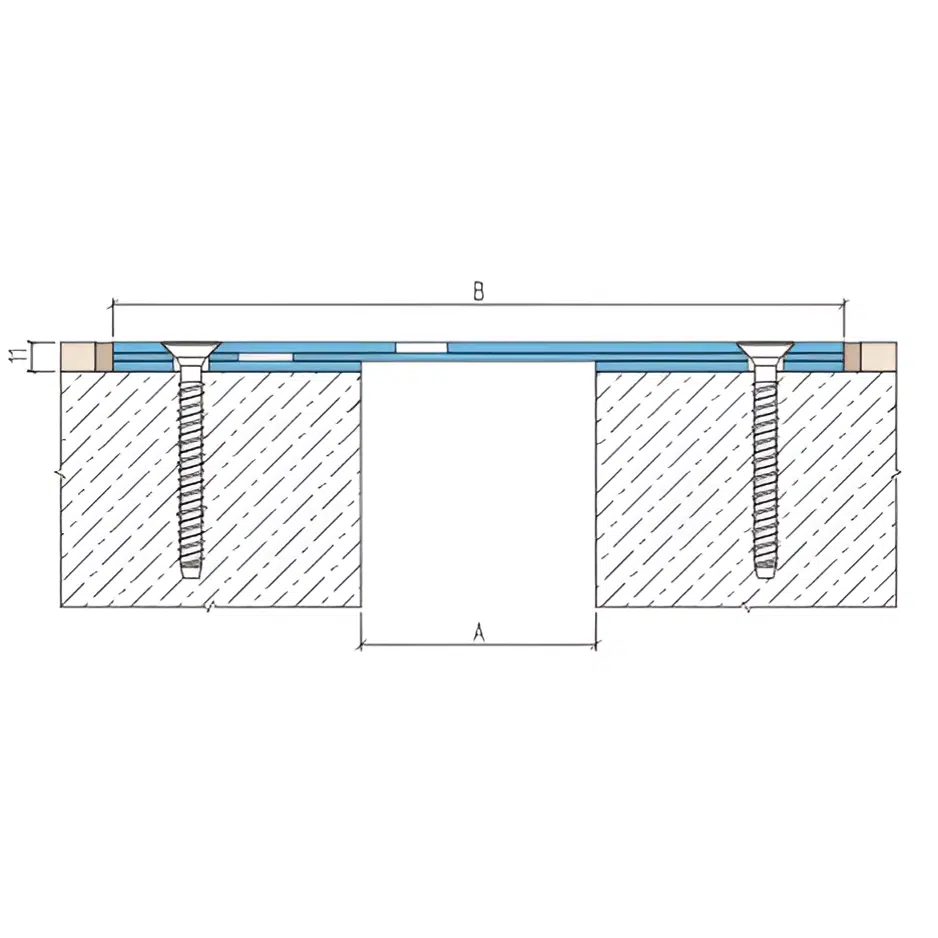

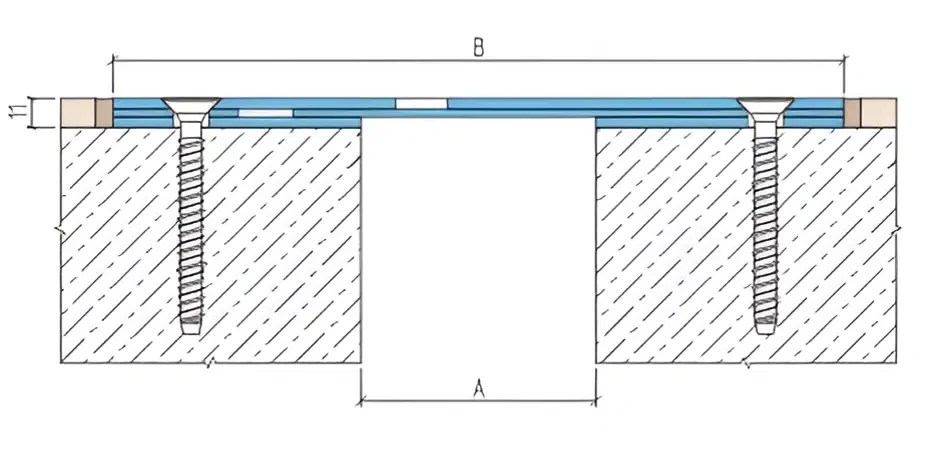

| А (ширина шва), мм | 40 |

| В (ширина вставки), мм | 200 |

| С (ширина профиля), мм | 200 |

| Высота профиля, мм | 11 |

| Длина | 3000 мм |

Универсальные требования:

- Соответствие СП 71.13330-2017;

- Проверка ровности основания мерной рейкой (допуск: ≤2 мм продольно, ≤1 мм поперечно);

- Момент затяжки крепежа: (указать для конкретной модели);

- Все параметры (А, В, С) определяются проектом.

⚠️ Важно! Для нестандартных условий проконсультируйтесь с ООО ТД «ГИДРОМИКС».

2009 — 2026 ГИДРОМИКС — Гидроизоляция, ремонт и защита — фундамента, вводов коммуникаций, кровли и водоемов

Политика конфиденциальности